Backup power is a $2B market in the U.S. alone. There are many applications for backup electrical power, such as in mission-critical technologies (computers, hospitals, telecommunications). In the case of telecommunication towers for cell phones, 8 hours of backup capability is mandated by law. Typically, backup is provided by batteries or capacitors, but more and more by fuel cells and gensets.

Although this slide pre-dates Lightfuel, the information and concept are still fresh.

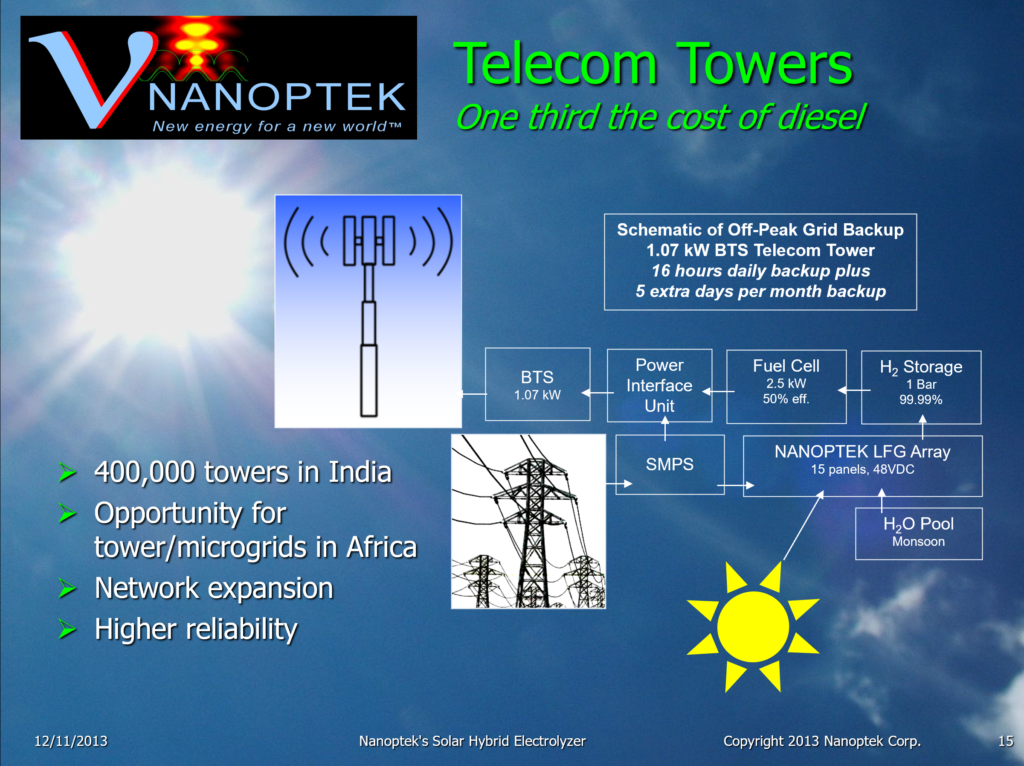

Telecommunication towers can particularly benefit from onsite hydrogen production with our LFG-80LH panels. There is an installed base of 2,000 fuel cells of 5 kW capability for backup power, and many of these are installed at cell towers. Most of these are in remote, hard to reach areas. Getting the heavy hydrogen cylinders to these remote sites can be costly and difficult, even sometimes requiring a crane to lift and place the cylinders over trees from the nearest access point.

Lightfuel’s Solar-Amplified Hydrogen Generators produce hydrogen on site not only during daylight hours, but into the night as well. Stored hydrogen is then available for for use on demand by fuel cells. Our pure and carbon-free hydrogen ensures that the fuel cell will not be fouled, and will live to its specified lifetime. Some fuel cells can even use the oxygen that our units co-produce for even higher efficiency.

In Africa, cell towers are typically powered by diesel generators. Just as with the delivery of hydrogen cylinders above, delivery of diesel fuel to towers that are in even more difficult to reach sites can be replaced with hydrogen supplied on site with our LFG-80LH panels. In fact, given the high daily average of sunlight in Africa, and LFG-80LH installation can supply the entire power requirement, rather than just backup power. And the hydrogen can even be used by the diesel generator with minor modifications (yes, the lifetime of the generator will be reduced by hydrogen embrittlement, but will still be longer and more economical than fuel cells).

For a 5 kW fuel cell with an assumed 60% conversion efficiency, and assuming AC is required with DC to AC conversion efficiency of 92%, the power backup requirement is [(5 kW x 8 hours)/(0.60 x 0.92)] = 72.5 kWh. Using the higher heating value (HHV) of hydrogen, 72.5 kWh/39.4 kWh/kg = 1.84 kg of hydrogen. So for a telecommunication tower in the Boston area with an average 4 hours of sunlight per day, and assuming that the backup is designed for one 8 hour backup per month, we need to produce 1.84 kg with 120 sunny hours, or 15.5 grams of hydrogen per sunny hour. Each LFG-80LH panel will produce 7.2 grams of hydrogen per hour, so 3 LFG-80LH panels would be needed (and maybe only 2 panels). A switching site would require 24 hours of backup, or 30 SHG300 panels.