Download EES pptx

Lightfuel’s LFG-80LH solar-amplified hydrogen generator panel uses sunlight and Nanoptek’s patented engineered band-gap photocatalytic photoanode to reduce the electrical power needed to split hydrogen from water to as little as 1/3 of that required by PEM or ½ of alkaline electrolyzers, for an electrical energy basis conversion efficiency of greater than 150%, and with solar-to-hydrogen conversion efficiency (STH%) of over 25%—-which is a World Record as of this writing (10/20/2020).

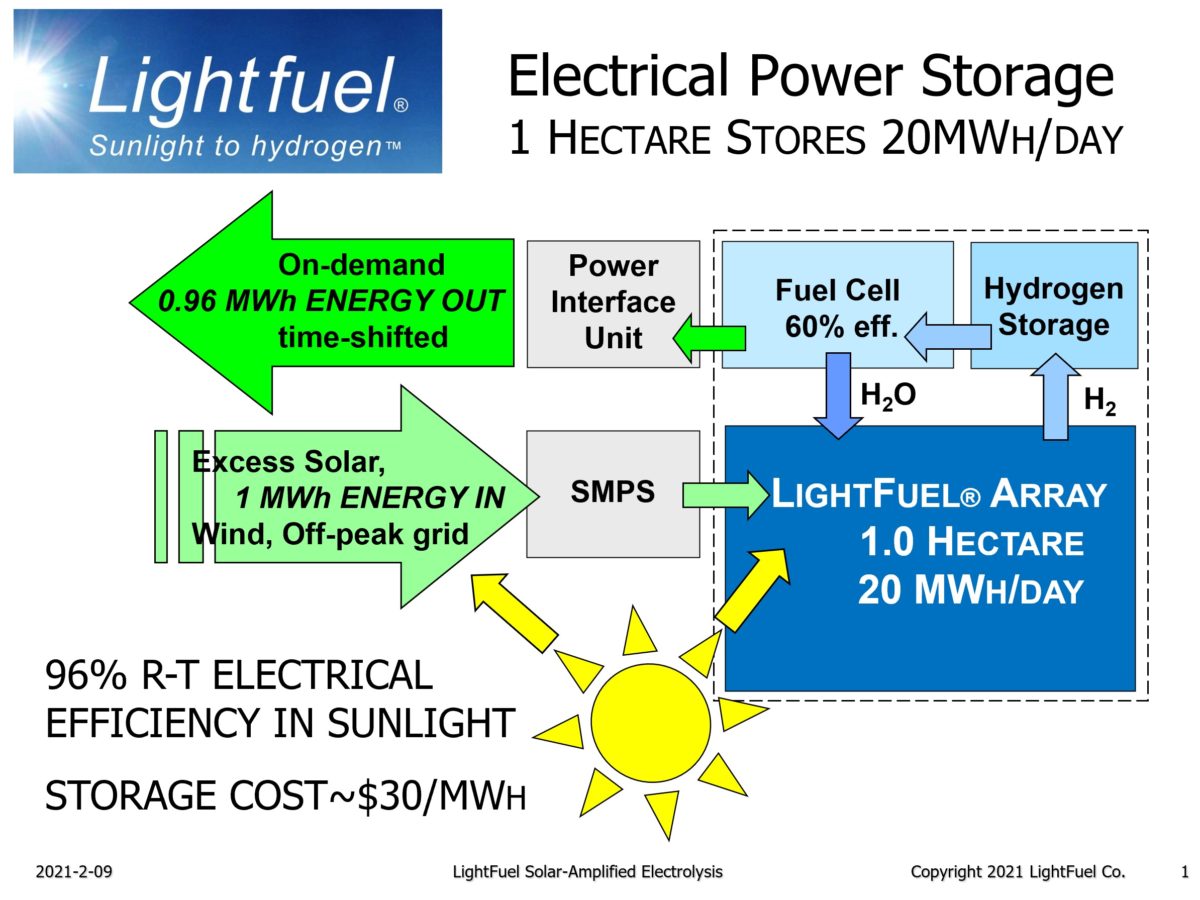

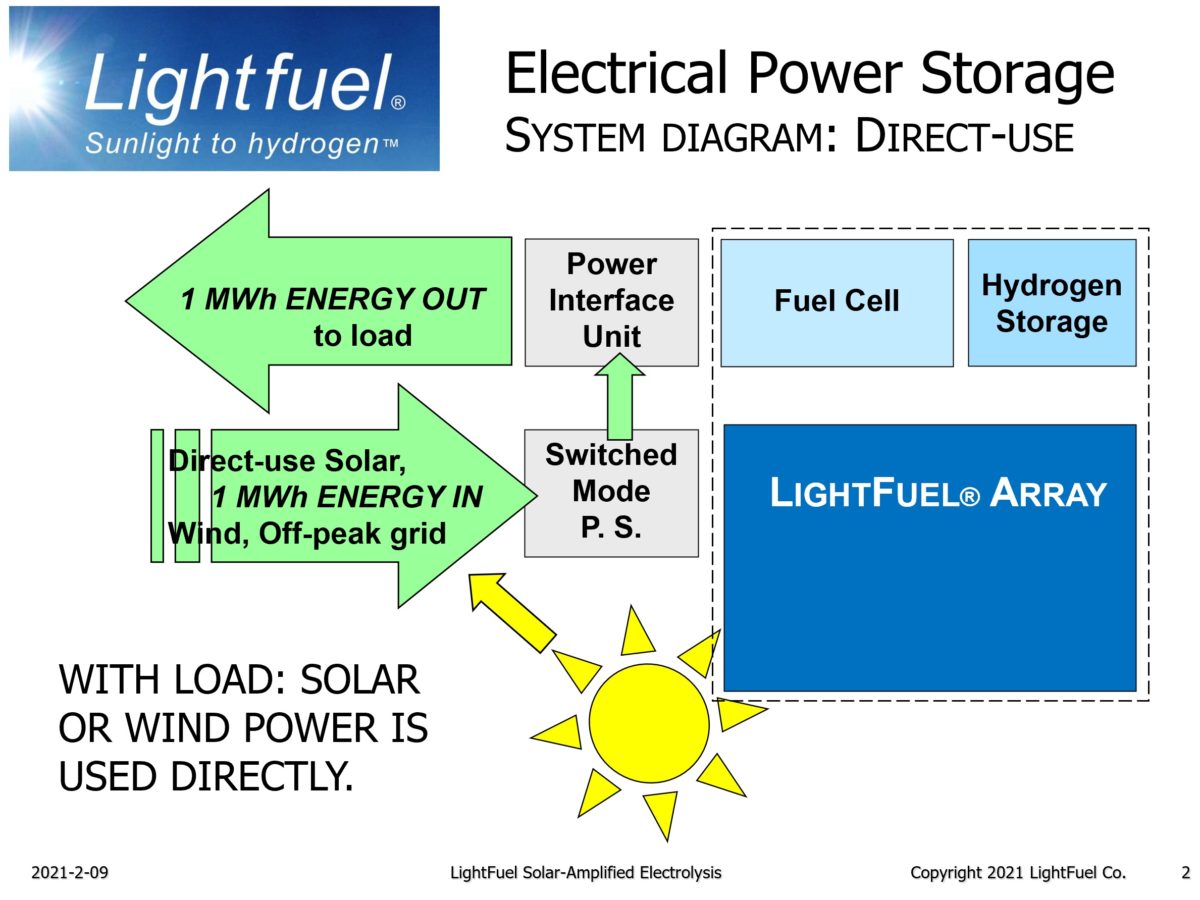

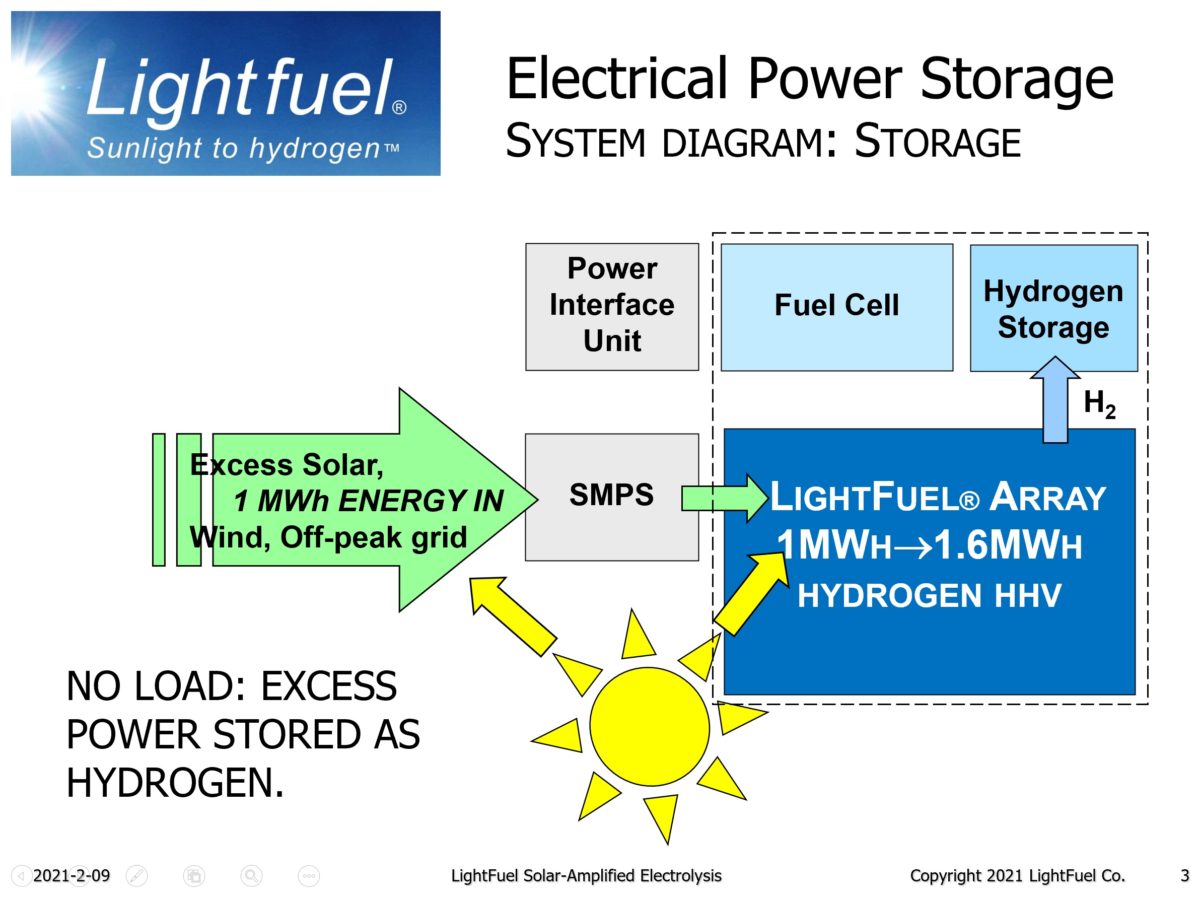

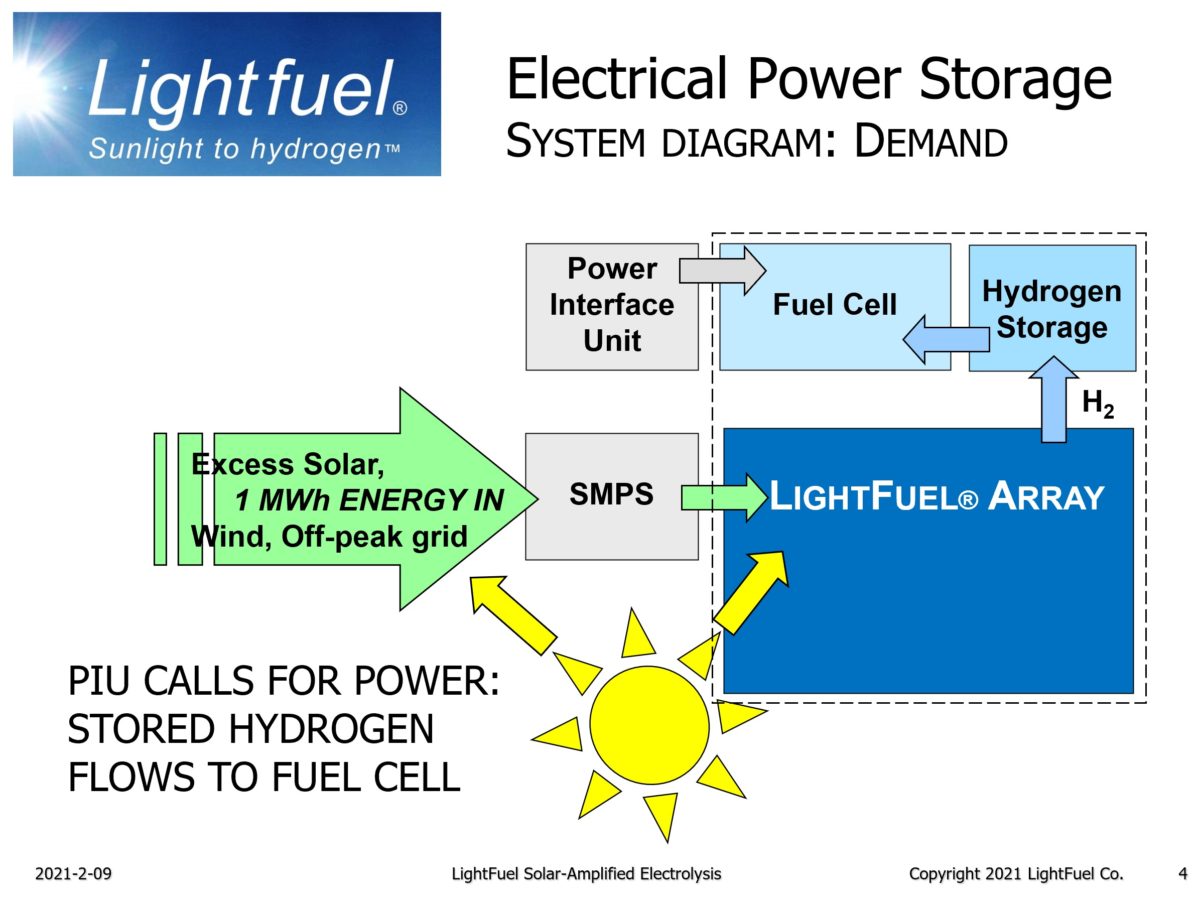

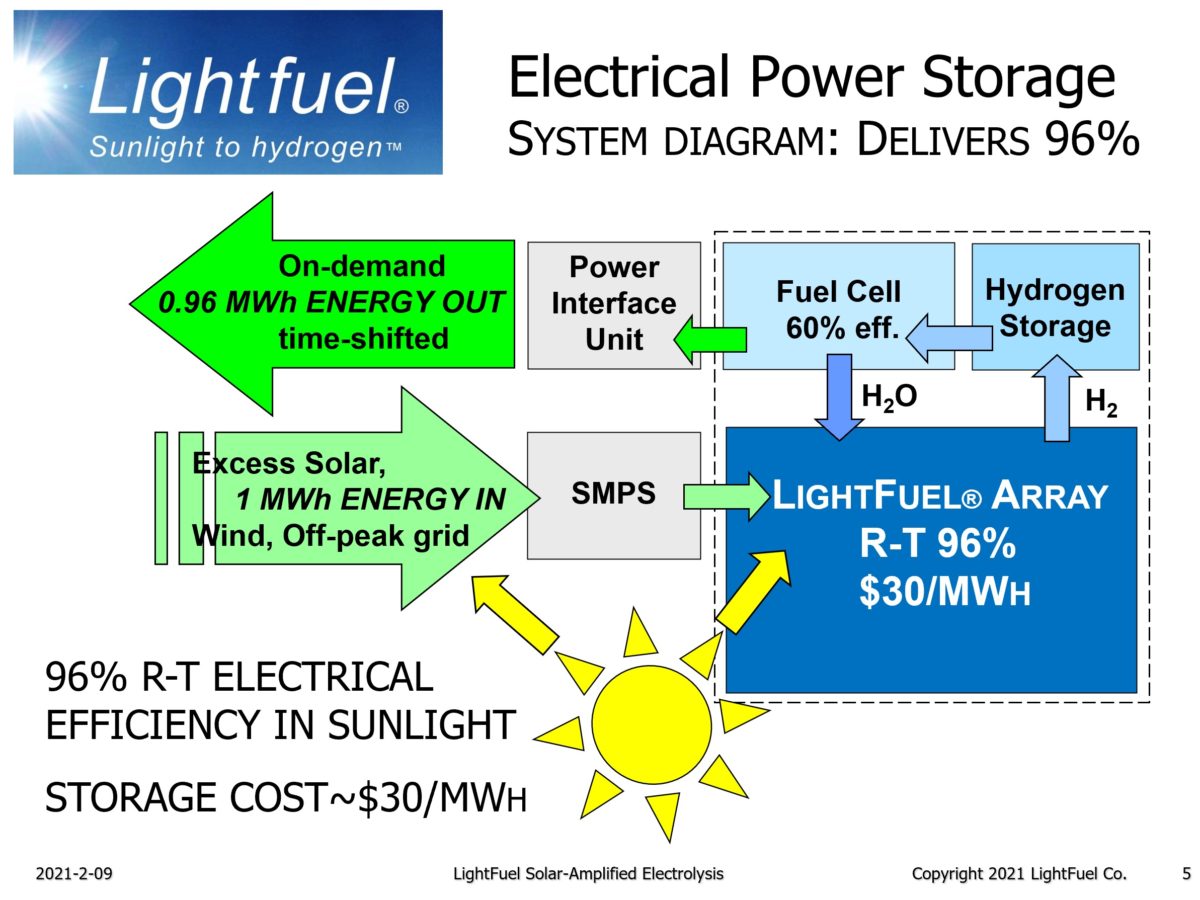

By providing efficient chemical storage of electrical energy, a LFG-80LH installation, in combination with hydrogen storage and fuel cell components from other manufacturers, enables nearly lossless 96% round-trip electrical energy storage (EES) and distributed electricity storage (DES). Utilities can save low-cost off-peak power to replace expensive peak-load capacity. Intermittent solar and wind power can be efficiently converted into hydrogen to provide a stable buffer to the grid, converting such clean sources into reliable “on demand” power to utilities.

Even after the sun has set, LFG-80LH panels continue to produce hydrogen at high-efficiency, as the effects of the sunlight persist in our technology. Integral conventional anodes continue to convert off-peak power from windfarms or the grid, through the night, into hydrogen chemical storage for later use, and with conversion efficiency as good as or better than many PEM electrolyzers.

Of course, no carbon is produced with renewable power input. But even with fossil-fueled grid power input, the sunlit panels reduce carbon 50% to 66% per unit of hydrogen produced compared to other electrolyzers.

LFG-80LH panel photoanodes’ highly efficient use of the shorter UV and blue wavelengths in sunlight means that panels will continue to generate hydrogen at up to 1/3 or more of its peak capacity on most overcast days, because these energetic wavelengths penetrate cloud cover more effectively than the rest of sunlight.

The modular 1.5m2 panel form-factor is easily interconnected to scale up to utility-size multi-acre MW installations, or down to off-grid backup and commercial installations. It stacks flat for economical warehousing and shipping. Optimum shallow-angle mounting means the panels can be packed more densely in fields or on roofs.