Most photocatalysts in use today are titania or variants thereof, and are activated primarily by ultraviolet (UV) light. Some manufacturers and academics advertise absorption of visible light, but the absorption is typically very weak. Also, it is not enough to just absorb the light if the light does not contribute to the photocatalytic activity (except of course for pigments).

Most photocatalysts in use today are titania or variants thereof, and are activated primarily by ultraviolet (UV) light. Some manufacturers and academics advertise absorption of visible light, but the absorption is typically very weak. Also, it is not enough to just absorb the light if the light does not contribute to the photocatalytic activity (except of course for pigments).

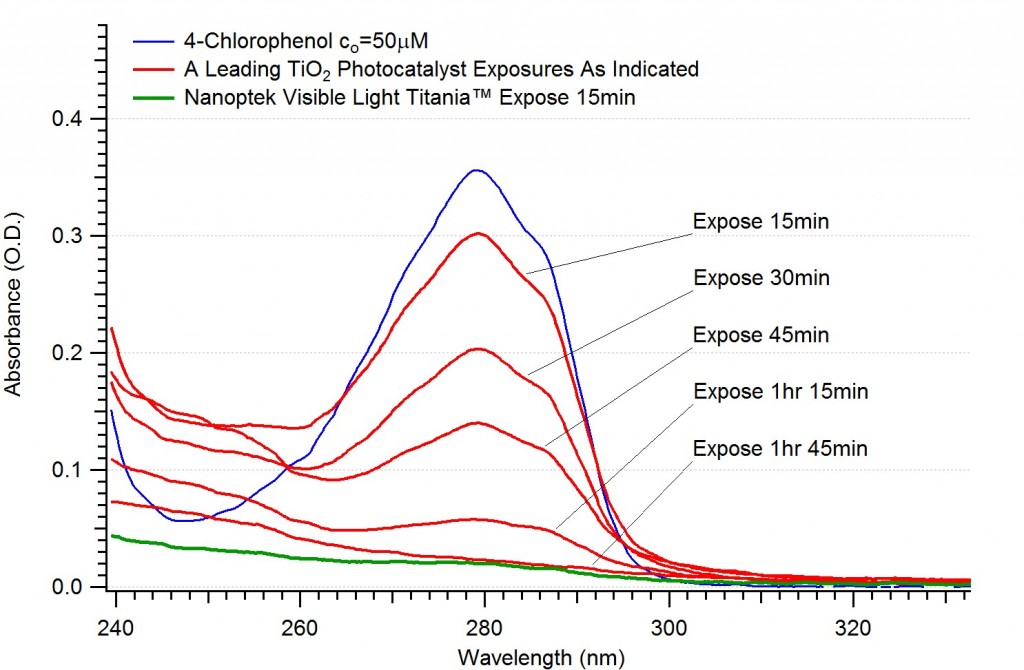

We test our visible light titania functionally. How quickly are methylene blue or rhodamine B dyes cleared? And are the dye molecules just bleached or actually dissociated? How quickly is chlorophenol degraded (left), and are there intermediates formed that may be just as undesirable? These are the measurements that matter. Email us for details of Total Organic Carbon (TOC) Analysis by independent testing lab VHG Labs (Manchester, NH).

We test our visible light titania functionally. How quickly are methylene blue or rhodamine B dyes cleared? And are the dye molecules just bleached or actually dissociated? How quickly is chlorophenol degraded (left), and are there intermediates formed that may be just as undesirable? These are the measurements that matter. Email us for details of Total Organic Carbon (TOC) Analysis by independent testing lab VHG Labs (Manchester, NH).

The image above right shows Nanoptek’s Visible Light Titania™ photocatalyst (gray, upper left corner) and Nanoptek Yellow™ pigment for plastics, ceramics, and paints (yellow, upper right corner) compared to normal titania (white, lower right corner), and a visible light photocatalyst from another manufacturer (light beige, lower left corner). The light absorption spectra of all but the beige sample can be seen here, but the deep yellow and grey colors of, respectively, our absorber and photocatalyst alone powerfully demonstrate how much visible light they absorb.